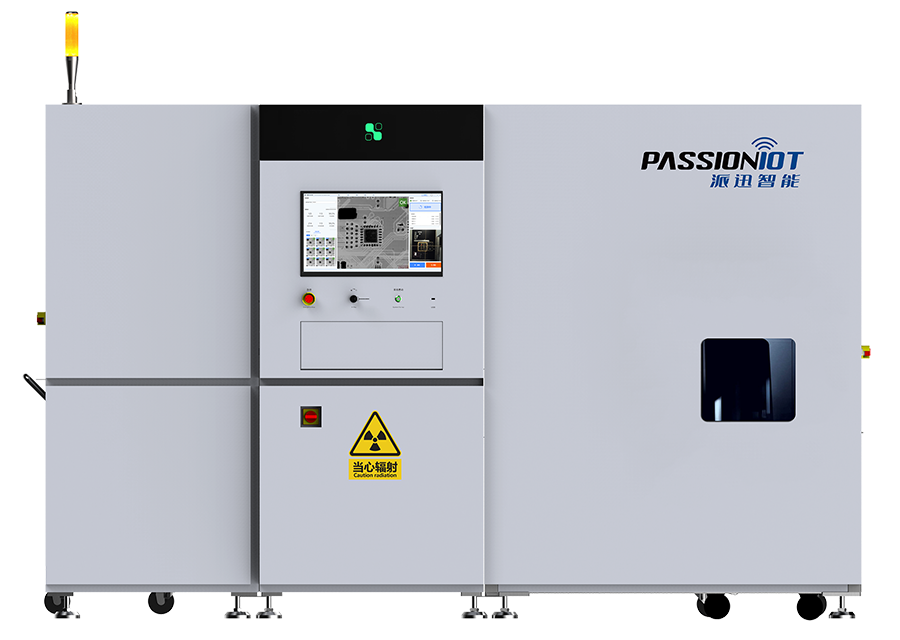

PassionIOT is a leader in innovative solutions for high-volume manufacturing, specializing in advanced technologies that enhance production efficiency. Their latest offering, the X-Ray SMD component counter, revolutionizes how businesses manage component counting on production lines, ensuring accuracy and reliability.

Efficient and Labor-Saving Inspection

The X-Ray SMD component counter is designed with efficiency in mind. With counting speeds reaching up to 13 seconds per piece, it significantly reduces the need for manual inspections. This feature not only saves labor costs but also enhances operational efficiency across production lines. Companies can rely on the SMD reel counter X-Ray for consistent and accurate counting, minimizing human error and streamlining the entire inspection process. By integrating such advanced technology, manufacturers can focus more on production and less on error-prone manual tasks.

Dual Verification for Error-Proofing

One of the standout features of the X-Ray SMD component counter is its dual verification system. This technology ensures that each count is accurate, providing a robust traceability system for SMD components. In high-volume production environments, reliability is key, and this dual verification process offers businesses peace of mind. The SMD reel counter X-Ray not only counts components but also guarantees that the data is trustworthy, making it an essential tool for manufacturers aiming for excellence in their production processes.

Conclusion

In conclusion, PassionIOT’s X-Ray SMD component counter stands out as a game-changer in the realm of component counting. With features like efficient inspection and dual verification, it meets the demands of modern manufacturing. By adopting this innovative solution, businesses can enhance their operational efficiency and ensure the highest standards of accuracy in their production lines. Embrace the future of manufacturing with PassionIOT’s cutting-edge technologies.